Why Your Heat Pump Compressor Is Critical to Home Comfort

Heat pump compressor repair is a critical task for maintaining year-round home comfort. When the compressor fails, your entire heating and cooling system stops working, making it one of the most important components in your HVAC system.

Quick Answer for Heat Pump Compressor Issues:

- Warning Signs: Strange noises (buzzing, grinding), poor heating/cooling, frequent breaker trips, or failure to start.

- Action Required: Professional repair is necessary due to high voltage and pressurized refrigerant.

- Lifespan: A well-maintained compressor lasts 10-15 years.

- Decision: The choice to repair or replace depends on the system’s age, warranty, and overall condition.

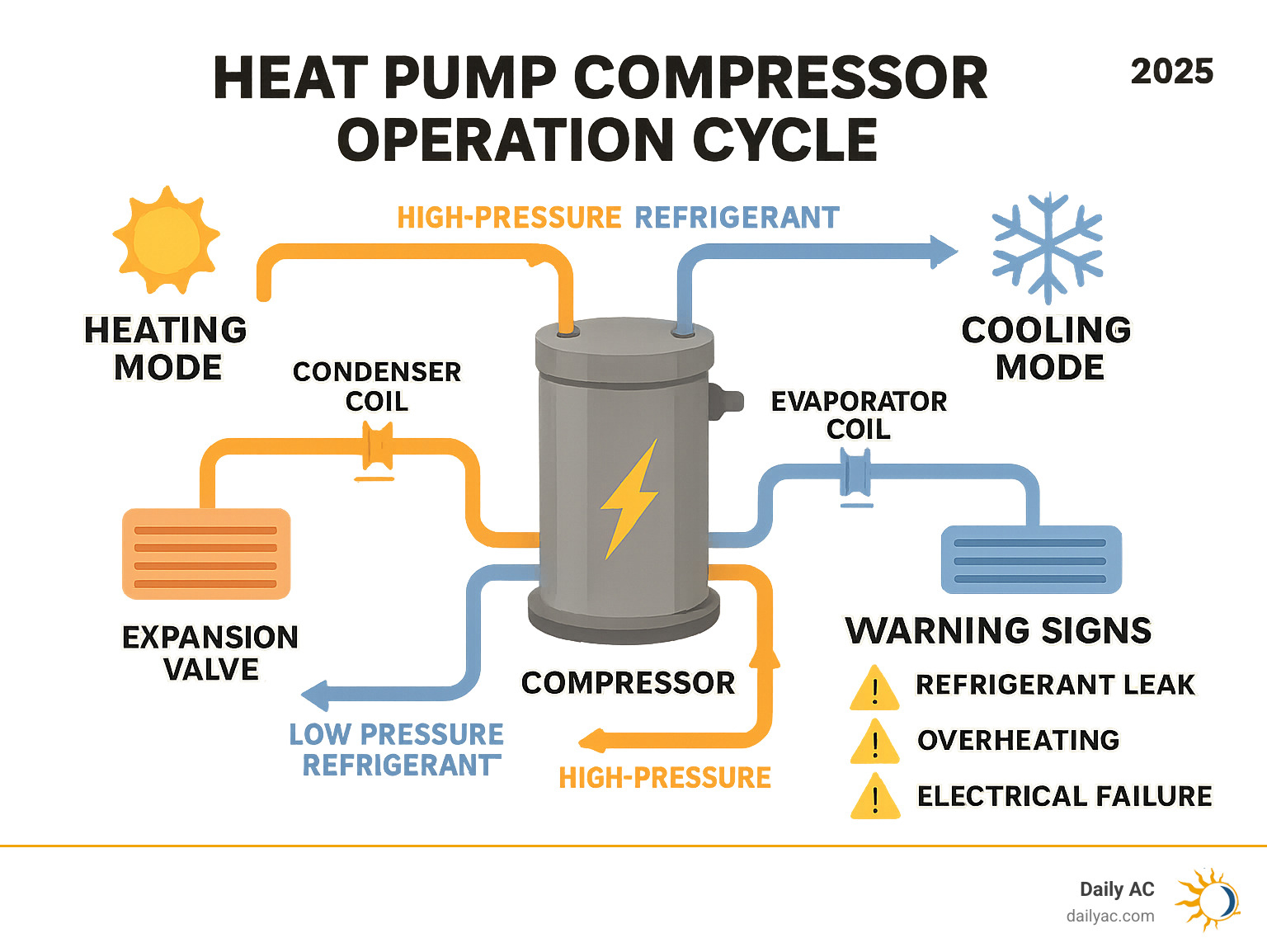

The compressor is the heart of your heat pump. It pressurizes and circulates refrigerant to move heat, allowing your system to warm your home in winter and cool it in summer. Without it, the heat transfer process cannot occur.

Most homeowners only notice the compressor when something goes wrong, but recognizing warning signs can prevent total system failure and costly emergency repairs. While compressors are durable, issues like electrical faults or refrigerant leaks can cause them to fail prematurely. Paying attention to symptoms like strange noises, reduced performance, or frequent cycling is key to catching problems early.

Understanding the Heart of Your Heat Pump: The Compressor

Your heat pump works by moving heat, not creating it. In winter, it extracts heat from the outside air and brings it inside. In summer, it reverses the process, pulling heat out of your home to keep you cool.

The compressor is the engine that drives this process. It pressurizes a special fluid called refrigerant, changing it from a low-pressure gas to a hot, high-pressure gas. This hot gas then circulates through the system, releasing heat where it’s needed.

A reversing valve acts as a traffic director for the refrigerant, switching its flow to provide either heating or cooling. This allows your heat pump to function year-round. The indoor and outdoor coils are where the heat exchange happens, absorbing and releasing heat as directed by the system.

For a deeper dive, our guides on Understanding Heat Pumps and Heat Pump Technology: Energy Efficient Solution offer more detail.

Key Components Relevant to the Compressor

What seems like a compressor failure can sometimes be an issue with a related component. Here are the key players:

- Refrigerant Lines: These copper lines carry refrigerant between the indoor and outdoor units. Leaks or blockages force the compressor to work harder, leading to strain and potential failure.

- Contactor: This is the electrical switch that turns the compressor on and off. If it fails, the compressor won’t receive power and will not start.

- Start Capacitor: This component provides the initial electrical jolt to start the compressor motor. A failing capacitor may cause a humming sound as the compressor tries but fails to start.

- Thermostat: As the system’s control center, a thermostat with dead batteries, incorrect settings, or faulty wiring can prevent the compressor from receiving the correct commands.

- Control Board: The system’s brain coordinates all functions. A faulty board can send incorrect signals to the compressor, causing erratic behavior.

Types of Heat Pump Compressors

Not all compressors are the same. The type in your system affects its performance, efficiency, and repair needs.

- Single-stage compressors operate on an all-or-nothing basis—they are either on at full capacity or off. This can create minor temperature fluctuations and puts more wear on the component due to frequent starting and stopping.

- Two-stage compressors have two operating levels: full capacity for extreme temperatures and a lower setting (around 65-70%) for milder days. This results in more consistent temperatures, better humidity control, and less strain on the compressor.

- Variable-speed compressors offer the most precise comfort by continuously adjusting their speed to meet your home’s exact needs. They run almost constantly at low speeds, providing exceptionally stable temperatures and quiet operation. While heat pump compressor repair for these units can be more complex, they deliver superior comfort and efficiency.

Telltale Signs of Compressor Distress

Your compressor will usually show signs of trouble before it fails completely. Recognizing these warnings can help you address problems before they lead to a total system breakdown. The most common signs include:

- Ineffective Heating or Cooling: Your home feels uncomfortable even when the system is running. This often means the compressor isn’t building enough pressure to circulate refrigerant effectively.

- Reduced Airflow: Weak airflow from your vents can indicate that the compressor is struggling, which impacts the entire system’s ability to move air.

- Tripped Circuit Breaker: A failing compressor often draws too much electricity, causing the circuit breaker to trip as a safety measure.

- System Won’t Start: If the outdoor unit is completely unresponsive, the compressor may have failed entirely.

If you hear unusual noises, our article on Why is my heat pump buzzing? can provide additional insight.

Strange Noises to Listen For

Unusual sounds from your outdoor unit are a clear signal that heat pump compressor repair may be needed.

- Loud Buzzing: Often points to an electrical issue, such as a failing start capacitor that can’t get the compressor motor running.

- Rattling or Clanking: Suggests that internal motor components are loose or worn out. While it could be simple debris, it usually signals mechanical wear.

- Hissing or Gurgling: This is often the sound of a refrigerant leak. Low refrigerant forces the compressor to work harder, risking serious damage.

- Grinding: A harsh, metal-on-metal sound is the most alarming. It typically means severe internal failure, and the compressor is likely beyond repair.

Concerning System Behavior

Beyond noises, certain operational issues put stress on the compressor and indicate a problem.

- Short-Cycling: The system turns on and off in rapid succession. This constant starting and stopping puts immense strain on the compressor.

- Overheating: The outdoor unit feels excessively hot or shuts down automatically. This can be caused by poor airflow or low refrigerant, forcing the compressor to overwork.

- Frost or Ice Buildup: While a light frost can be normal, thick ice on the coils points to an airflow or refrigerant problem. This makes the compressor work much harder.

- Increased Energy Bills: A sudden spike in your electricity costs without a change in usage suggests your compressor is running inefficiently and consuming excess power.

Common Culprits: What Causes Compressor Failure?

Heat pump compressors are built to last, but they aren’t invincible. Understanding the common causes of failure helps in diagnosing issues and preventing future problems. Most failures stem from electrical issues, refrigerant problems, contamination, or simple wear and tear.

As a diagram of a heat pump system shows, all components are interconnected. A problem in one area can quickly cascade and put excessive strain on the compressor.

Electrical and Mechanical Failures

Since the compressor is a large motor, electrical faults are a leading cause of failure that we see on heat pump compressor repair calls.

- Failed Capacitors: The start capacitor provides a jolt to start the motor, while the run capacitor keeps it running efficiently. A failed start capacitor will cause a humming sound, while a failed run capacitor can lead to overheating and motor burnout.

- Damaged Wiring: Corrosion, frayed wires, or loose connections from Florida’s humidity can create inconsistent power, starving the compressor or hitting it with damaging surges.

- Burnt-Out Motor: Persistent electrical issues or continuous strain can cause the internal motor to overheat and burn out, which is typically a fatal failure.

- Seized Bearings: Lack of lubrication or excessive heat can cause internal bearings to lock up, creating a grinding noise and stopping the compressor from turning.

- Valve Failure: Failure of the internal valves that control refrigerant pressure will prevent the compressor from working effectively, resulting in poor performance.

Refrigerant and Contamination Problems

Refrigerant is the lifeblood of your system, and problems with it are a frequent cause of compressor failure.

- Refrigerant Leaks: Low refrigerant levels force the compressor to work much harder to move heat, leading to overheating and eventual failure.

- Incorrect Refrigerant Charge: Both too little (undercharge) and too much (overcharge) refrigerant are damaging. An undercharged system causes overworking, while an overcharged one creates dangerously high pressures.

- Acid Buildup: When a motor burns out, it can release acid into the refrigerant. This corrosive acid circulates through the system and can destroy a new compressor if not properly flushed out.

- Dirt and Debris: Contaminants like dirt or metal shavings act like sandpaper on internal components, causing premature wear.

- Clogged Air Filters: A blocked filter can cause the indoor coil to freeze, sending liquid refrigerant back to the compressor. This condition, known as “liquid slugging,” can cause immediate and severe damage.

Handling refrigerant requires certified technicians to comply with federal environmental laws, especially for older systems using R-22 refrigerant.

The Homeowner’s Checklist vs. Professional Heat Pump Compressor Repair

When your heat pump acts up, it’s tempting to try a DIY fix. However, heat pump compressor repair involves high voltage electricity and pressurized refrigerant, both of which pose significant safety risks. Attempting complex repairs without proper training and specialized tools can lead to injury or cause more extensive damage to your system.

A professional diagnosis is essential to correctly identify the root cause. Using equipment like multimeters and refrigerant gauges, a technician can distinguish between a failed compressor and a less severe issue, ensuring the right repair is performed.

What You Can Safely Check

Before calling for service, performing these simple checks may resolve the issue or provide valuable information for your technician.

- Thermostat Settings: Ensure it’s set to “heat” or “cool” and that the target temperature requires the system to run. Check and replace the batteries if the display is dim or blank.

- Air Filter Condition: A clogged air filter restricts airflow and can cause the system to overheat or shut down. Check your filter monthly and replace it if it’s dirty.

- Circuit Breaker Panel: Find the breaker for your heat pump. If it has tripped, turn it fully off and then back on once. If it trips again, leave it off and call a professional, as this indicates a serious electrical problem.

- Outdoor Unit: Clear away any leaves, grass clippings, or other debris from around the outdoor unit. Ensure there is at least two feet of clearance on all sides for proper airflow.

Why You Need an Expert for Heat Pump Compressor Repair

Beyond basic troubleshooting, compressor work is a job for a trained professional. Here’s why:

- Diagnosing the Root Cause: An expert can determine if the compressor itself has failed or if the problem is a faulty capacitor, a refrigerant leak, or a bad control board. This prevents unnecessary and expensive repairs.

- Handling Refrigerant Safely: Only EPA-certified technicians are legally allowed to handle refrigerant. This is crucial for your safety and to protect the environment.

- Safe Electrical Testing: Heat pumps use high-voltage power. Professionals know how to safely test components like capacitors, which can hold a dangerous charge even when the power is off.

- Ensuring Part Compatibility: Compressors are not interchangeable. A technician will source the correct OEM part for your specific model to ensure proper function and prevent further damage.

- Preventing Further Damage: A single mistake during a DIY repair can cascade into a much larger problem, potentially requiring a full system replacement. A professional repair protects your investment.

At Daily A/C INC., our technicians have the training and tools to diagnose and fix compressor issues safely and effectively, restoring your comfort without risk.

The Big Decision: Repair the Compressor or Replace the System?

When your compressor fails, you face a major decision: invest in heat pump compressor repair or replace the entire system? The right choice depends on several key factors, including your system’s age, warranty status, and overall condition. It’s about finding the most sensible long-term solution for your home and budget.

Heat pumps typically last 15 years or more with proper maintenance. If your unit is under 10 years old and otherwise in good shape, a repair is often the most logical path. However, for an older system showing multiple signs of wear, replacement may be a wiser investment.

Our guides on Whether to Repair or Replace Your Heat Pump System and A Guide to Heat Pump Selection can provide more detailed information to help you decide.

Factors Favoring Repair

In many cases, heat pump compressor repair is the best option.

- Unit is Under 10 Years Old: A system that is less than a decade old likely has many years of service left. Replacing the compressor can be a cost-effective way to extend its life.

- Warranty Coverage: Most compressors have a 10-year parts warranty. If the failure is covered, you may only be responsible for labor costs, making repair a clear choice.

- Good Overall System Condition: If the indoor and outdoor coils, fan motors, and other components are in good shape, the system can reliably support a new compressor.

- Minor Component Failure: Sometimes the issue isn’t the compressor itself but a related part like a start capacitor or contactor. These are far less expensive to repair.

Factors Favoring Full System Replacement

In other situations, a full replacement is the smarter long-term financial decision.

| Factor | Repair Compressor | Replace Entire System |

|---|---|---|

| System Age | Ideal for units under 10 years old | Recommended for units over 10-15 years old |

| Warranty | Potentially covered if compressor is under warranty | Full warranty on all new components |

| Refrigerant Type | Expensive if using phased-out R-22 | Modern refrigerants that are readily available |

| Efficiency | Maintains current efficiency levels | Significant efficiency improvements |

| Future Repairs | Other aging components may fail soon | Years of reliable operation ahead |

| Technology | Keeps existing technology | Access to latest comfort features |

- Age Over 10-15 Years: In an older system, other major components are also nearing the end of their lifespan. A new compressor may be followed by another costly repair soon.

- Uses R-22 Refrigerant: This refrigerant was phased out in 2020. It is now extremely expensive and difficult to source, making repairs on older systems impractical.

- Frequent Breakdowns: If you’ve had multiple repairs in recent years, it’s a sign that the system is unreliable. Replacement offers a fresh start.

- Improved Energy Efficiency: Modern heat pumps are significantly more efficient than older models. The long-term energy savings from a new, high-SEER system can help offset the initial investment. Learn more about the remarkable efficiency of modern heat pumps.

We can help you weigh these factors to make an informed choice that aligns with your goals and budget.

Conclusion: Restoring Your Home’s Comfort

Your heat pump’s compressor is the core of your home’s comfort system. When it struggles, your ability to stay cool in the Florida heat or warm during a cold snap is compromised. Warning signs like strange buzzing sounds, poor performance, or breaker trips are your system’s call for help.

While it may be tempting to investigate on your own, heat pump compressor repair is not a DIY job. It involves high-voltage electricity and pressurized refrigerants that require professional handling for your safety and the health of your system. Professional repair is essential to diagnose the problem correctly and perform a lasting fix.

The decision to repair or replace depends on your system’s age, condition, and warranty status. A newer unit may only need a simple repair, while an older, inefficient system might be ready for replacement, offering you long-term comfort and peace of mind.

At Daily A/C INC., we pride ourselves on honest assessments and quality work. Our friendly, capable team serves families throughout Davie, Plantation, Miramar, Fort Lauderdale, North Miami Beach, West Palm Beach, and Doral. We take the time to explain your options, helping you make the best decision for your home.

Don’t let a failing compressor disrupt your comfort. Schedule your heat pump service in Davie, FL with us today, and let our experts get your system back on track.